Student-Designed Rover Could Improve Safety for Facilities Staff [video]

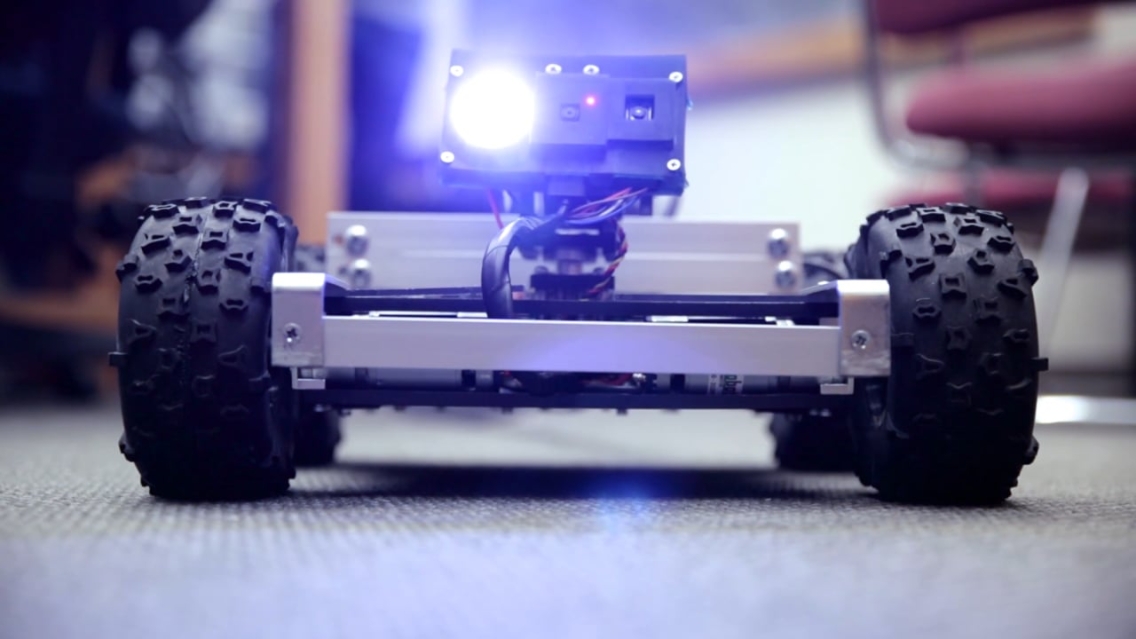

MIDDLEBURY, Vt. – With its Xbox controller and dune buggy wheels, the new RIVIR vehicle could easily be mistaken for a toy rather than the result of weeks of mental and physical laboring by a team of Middlebury students. But nothing could be further from the truth. The simple-looking device, whose name stands for Remote Inspection Vehicle with Infrared, is capable of inspecting tight places where people can’t–or shouldn’t–fit, and relaying important data back to the humans controlling it above ground.

The students who first imagined the vehicle during winter term 2016, then completed it during a 8-week STEM Innovation program last summer, are hoping it will be useful to Middlebury’s facilities department when they conduct their annual steam system inspections this spring.

When they began the project, the seven students knew they wanted to design a drone or some kind of remote vehicle that would decrease the need for humans in a tight space. That led them to Facilities Director Mike Moser, who said such a device might improve how his staff evaluated steam trap efficiency.

“I shared potential ‘real-world problems’ that needed to be solved,” said Moser. “The students applied this information to their work and tailored development of the RIVIR to meet these needs.” Moser said the goal was not to displace staff, but rather to develop and provide technology that could perform the detailed work accurately and safely.

RIVIR allows a user to lower the vehicle into a steam room via manhole and navigate to the desired steam trap. From there, it can relay both visual and thermal images of the trap back to a computer to evaluate how it’s working. The students collaborated with Moser’s team to test the vehicle in a few steam rooms around campus over the summer, each time gathering helpful feedback about what worked and what needed improvement.

“Having a test location allowed us to really consolidate our ideas down into a single focus,” said STEM team member Annie Cowan ’18. She said the enthusiastic response from facilities staff made the group rethink their goals and tailor the vehicle specifically for Middlebury’s needs.

Prototype vehicles–all precursors to the final RIVIR–line a shelf on one wall of the Bicentennial Hall lab where the students did their work. The display gives a sense of how their thinking grew over time. The first design, a miniature tank, bears practically no resemblance to the sleek, low-slung vehicle they ended up with last summer.

With their Facilities Services client in mind, the STEM team tried to make everything user-friendly, which was challenging at times. For example, RIVIR contained multiple rechargeable batteries in its first iterations.

“In the lab, multiple batteries are no problem,” said Noah Graham, professor of physics and one of the students’ advisors. “But when you hand it off to someone working in the field and tell them you need to charge this battery and that battery, it creates barriers.” Figuring out how to make one battery charge the entire device then became an important design challenge for the team, Graham said.

Watching how efficiently RIVIR works, it would be easy to think the process was smooth. In reality, of course, it was a long and sometimes messy path with countless challenges. “We had to write a final paper and it ended up being fifty pages,” said Cowan. “But honestly,” she laughed, “if we had to report on everything that didn’t work, it would be more like a thousand!”

The STEM Innovation team that worked on RIVIR included Shougat Barua ’19, Annie Cowan ’18, Bennett Doherty ’18, Jennifer Johnson ’18, Aayam Poudel ’18, Robert Pritchard ’19, and Jonah Simon ’18 with guidance from professors Jeremy Ward (biology), Noah Graham (physics), and Frank Swenton (mathematics). Read more about STEM Innovation at Middlebury.